The 15-Second Trick For Roar Solutions

The 15-Second Trick For Roar Solutions

Blog Article

Not known Details About Roar Solutions

Table of ContentsUnknown Facts About Roar SolutionsGetting The Roar Solutions To WorkThe 8-Minute Rule for Roar SolutionsSome Known Factual Statements About Roar Solutions

The devices register is a thorough data source of equipment documents that consists of a minimum set of fields to determine each item's location, technical criteria, Ex-spouse classification, age, and ecological information. This information is critical for monitoring and taking care of the tools effectively within hazardous locations. On the other hand, for routine or RBI sampling examinations, the grade will certainly be a combination of Thorough and Close assessments. The proportion of In-depth to Shut inspections will be established by the Equipment Threat, which is assessed based on ignition threat (the chance of a source of ignition versus the possibility of a flammable atmosphere )and the unsafe location classification( Zone 0, 1, or 2). This variant will additionally affect the resourcing requirements for work preparation. When Great deals are defined, you can develop tasting plans based on the example size of each Great deal, which describes the variety of random devices products to be examined. To establish the required sample dimension, 2 aspects need to be examined: the dimension of the Lot and the classification of inspection, which shows the level of effort that must be used( reduced, normal, or boosted )to the examination of the Lot. By incorporating the group of evaluation with the Whole lot size, you can after that establish the appropriate being rejected requirements for a sample, suggesting the permitted number of malfunctioning things found within that example. For even more information on this process, please describe the Energy Institute Guidelines. The IEC 60079 conventional suggests that the maximum period between inspections need to not exceed three years. EEHA assessments will likewise be carried out outside of RBI campaigns as part of set up upkeep and equipment overhauls or repair services. These examinations can be attributed towards the RBI example sizes within the impacted Great deals. EEHA evaluations are carried out to identify faults in electric devices. A heavy scoring system is important, as a single item of equipment may have several mistakes, each with differing levels of ignition danger. If the mixed rating of both evaluations is less than twice the mistake rating, the Lot is deemed appropriate. If the Great deal is still considered undesirable, it should undertake a full assessment or justification, which may cause more stringent evaluation procedures. Accepted Lot: The sources of any type of faults are determined. If an usual failing setting is discovered, additional equipment may need assessment and repair. Faults are categorized by seriousness( Safety and security, Integrity, Home cleaning ), ensuring that immediate issues are analyzed and dealt with quickly to mitigate any type of impact on safety or procedures. The EEHA database ought to track and tape the lifecycle of faults in addition to the restorative actions taken. Implementing a durable Risk-Based Inspection( RBI )method is vital for guaranteeing compliance and safety and security in taking care of Electrical Devices in Hazardous Locations( EEHA). Automated Fault Scoring and Lifecycle Monitoring: Easily manage mistakes and track their lifecycle to improve assessment precision. The introduction of this support for risk-based examination additionally reinforces Inspectivity's setting as a best-in-class service for regulatory conformity, in addition to for any kind of asset-centric assessment usage situation. If you want discovering more, we welcome you to ask for a demo and uncover just how our option can transform your EEHA administration procedures.

With over 10 years of consolidated Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to promote the importance of proficiency of all personnel involved in the Hazardous Location area in 2019. In 2021, our partnership with IndEx and Technology Ability International (TSI) noted a milestone in the Saipex roadway to proceed Ex lover improvement.

Roar Solutions Things To Know Before You Get This

In terms of explosive danger, an unsafe location is an environment in which an eruptive atmosphere exists (or might be expected to be existing) in quantities that need special safety measures for the building and construction, installation and use tools. In this short article we discover the difficulties encountered in the workplace, the danger control procedures, and the required competencies to function safely.

(https://hub.docker.com/u/roarsolutions?_gl=1*1e9kzbw*_ga*ODg4MTc2NDIuMTczMzIyNDYzMg..*_ga_XJWPQMJYHQ*MTczMzIyNDYzMS4xLjEuMTczMzIyNDg4MS4yOS4wLjA.)

These substances can, in particular problems, develop explosive atmospheres and these can have significant and heartbreaking effects. Many of us are acquainted with the fire triangle remove any one of the three elements and the fire can not take place, yet what does this mean in the context of unsafe locations?

This is after that validated with assessment and testing and is protected throughout the life of the setup by utilizing the correct maintenance methods, supplemented by routine assessment. When all these actions are taken, they ought to additionally be recorded. The verification dossier consists of information such as the hazardous area category drawing, suppliers' documents, devices qualification, style drawings and calculations, inspection records, and documents of a person's expertise and proceeding specialist development (CPD), such as via ECA's eCOMS software program.

The Roar Solutions Diaries

It is imperative that pupils understand and have a comprehensive expertise as to exactly what constitutes a harmful area. The student ought to also recognize why training is essential prior to attempting to handle work or defining devices right into a dangerous area. These locations are also referred to as classified locations and are specified as locations which have a high likelihood of an explosion since of pop over here the possible presence of flammable gases, vapors, dusts and so on.

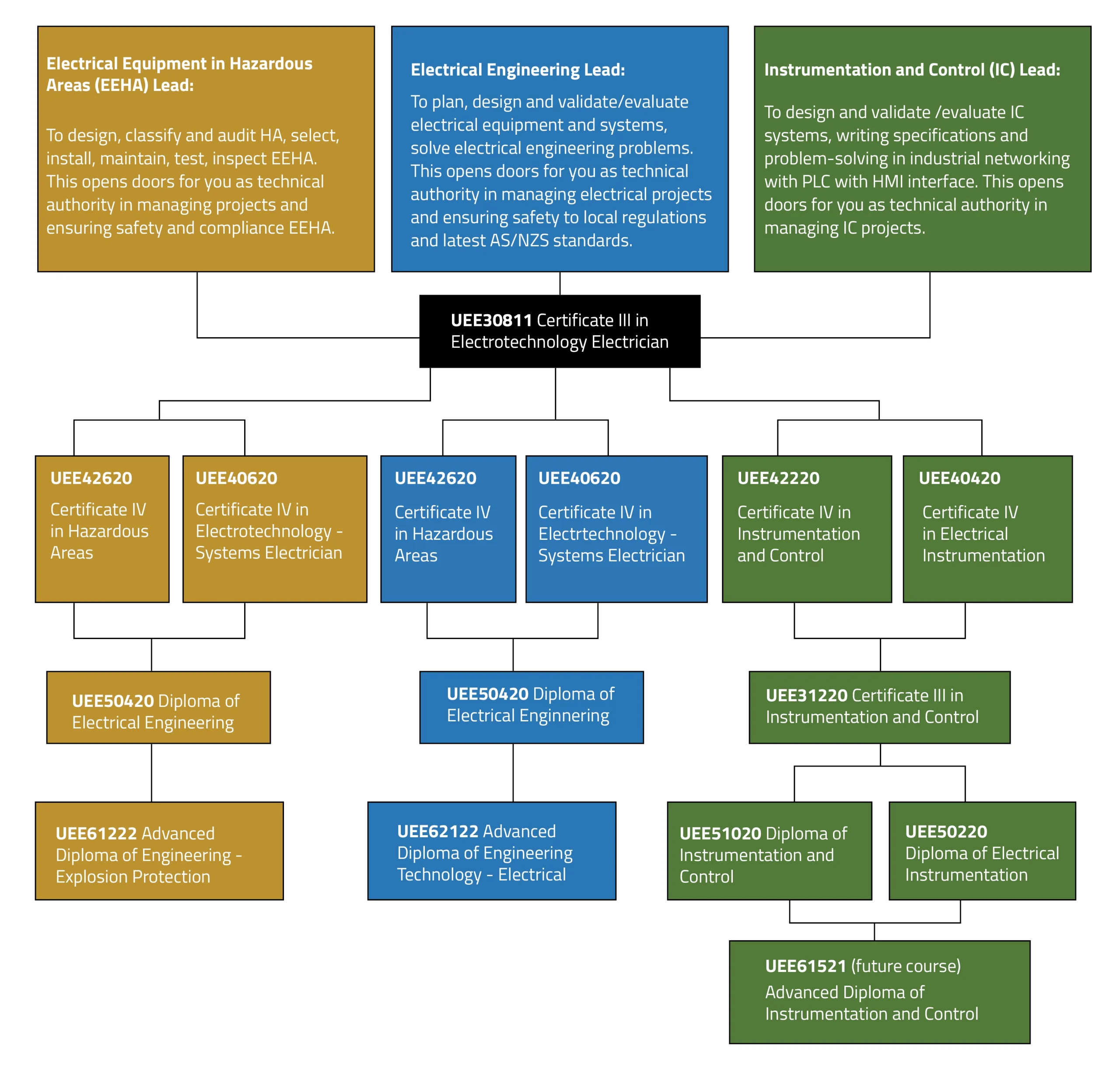

Industries which contain hazardous locations are currently requiring that electric workers that are defining or working in these areas should have a hazardous area credentials that regards them skilled. Jobs in these sectors are extremely rewarding so you need to be prepared. To meet this demand for the market, country wide acknowledged training in Certificate IV in Unsafe location Electrical and EEHA training on the development of proficient experts.

Get This Report about Roar Solutions

Tech Skills Australia is a Registered Training Company offering you with the most cost effective and quickest method in getting your qualification - eeha courses. Our teachers are sector certified and have a number of years of process experience. Our courses have actually aided thousands of individuals from business supervisors to daily employees in obtaining a strong hold on this not so complicated yet high danger training

The training likewise consists of determining the unsafe locations, resources of explosion and the properties of hazardous products in addition to the responsibilities and features of all celebrations, guidelines, systems, standards and technique codes connected to dangerous areas. We give instrumentation and hazardous area services that remain in conformity to most current AS/NZS and global market requirements.

Report this page